Electric Compressors

With more well-pads gaining access to the power grid, electrification of the artificial lift compressor package market is growing rapidly. The push for net zero emissions, a growing need for a more sustainable operational environment, and the low cost maintenance benefits of electric drive compression packages are just a few reasons why their popularity continues to grow.

At McClung we’ve been designing and fabricating electric drive compression packages since 2012. With over 600 successful builds under our belt, we’ve quickly built a reputation as a leader in both custom and pre-packaged electric compression packaging. In fact, according to the Gas Compression Association, in 2020 McClung built more electric units than anyone else in the country.

Maybe you’re an old pro and have been using electric compression for years or maybe your looking to implement your first electric unit. Regardless of where you are in the process, we’re here with the engineering and manufacturing expertise to make your operation a success. Let us know how we can help make your electric compression package vision a reality.

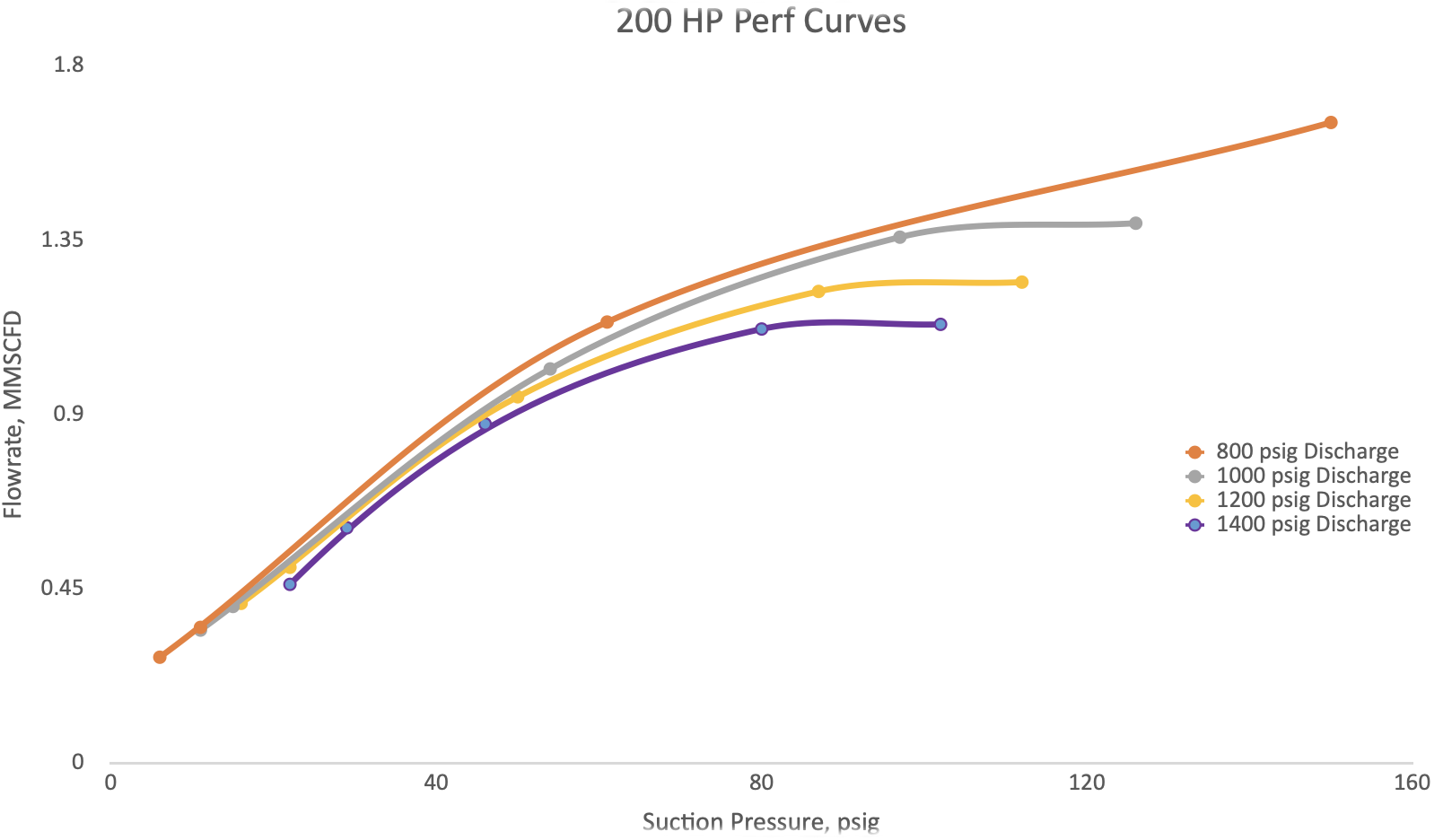

200HP-JGQ/2 ELECTRIC COMPRESSION

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel

- Rugged four-runner I-beam skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Electric Heat Tracing

- Insulated scrubbers

- Automatic makeup/recycle valve

Compressor: Ariel JGQ/2

Cylinder Size MAWP

1st Stage Cylinder 7.5” JG 600 psig

2nd Stage Cylinder 5.125” P10-HE 1200 psig

3rd Stage Cylinder 3.25” P11-CE 1800 psig

Cooler: 48” Induced Draft, Vertical Discharge

Control System: Murphy/TECO

Overall Dimensions: 23’ L X 9’ W X 10’ H

Shipping Weight: 26,000 lbs

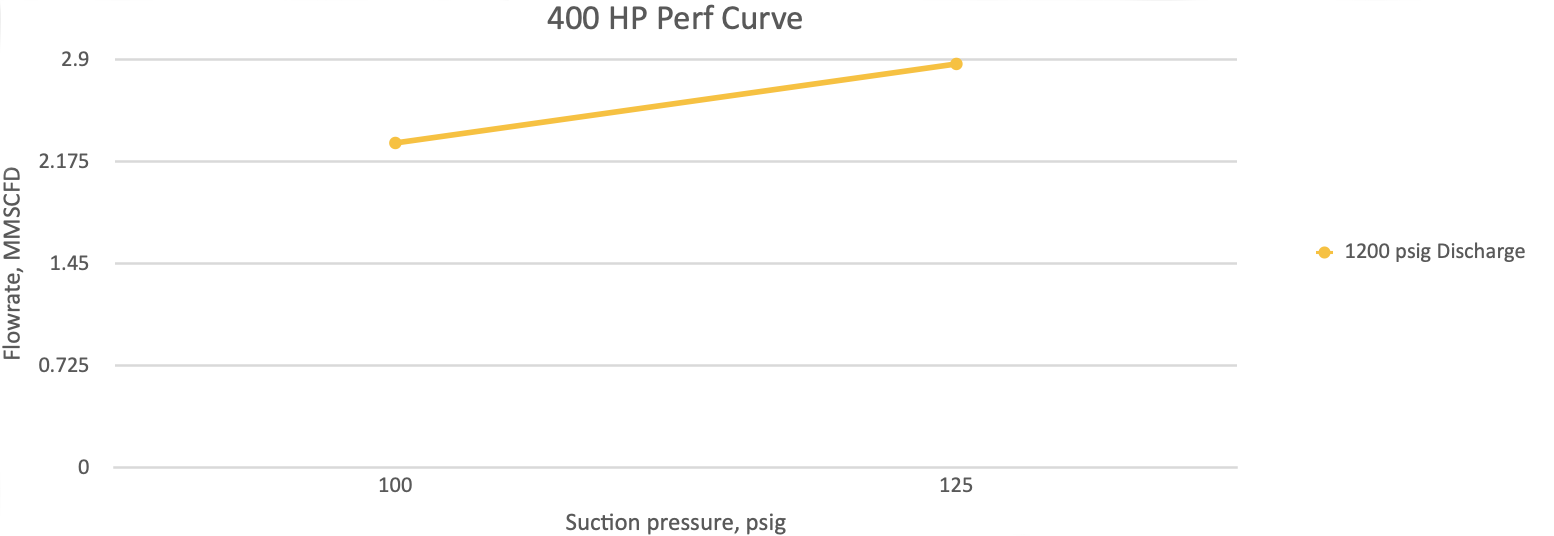

400HP-JGA/4 ELECTRIC COMPRESSION

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA3 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel

- Rugged four-runner I-beam skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Electric Heat Tracing

- Insulated scrubbers

- Automatic makeup/recycle valve

Compressor: Ariel JGA/4

Cylinder Size MAWP

1st Stage Cylinders (2) 7.5” JG 600 psig

2nd Stage Cylinder 5.125” JG 865 psig

3rd Stage Cylinder 3.375” JG 1640 psig

Cooler: 72” Vertical Forced Draft

Control System: Murphy/TECO

Overall Dimensions: 27’ L X 11’ W X 11’ H

Shipping Weight: 47,500 lbs

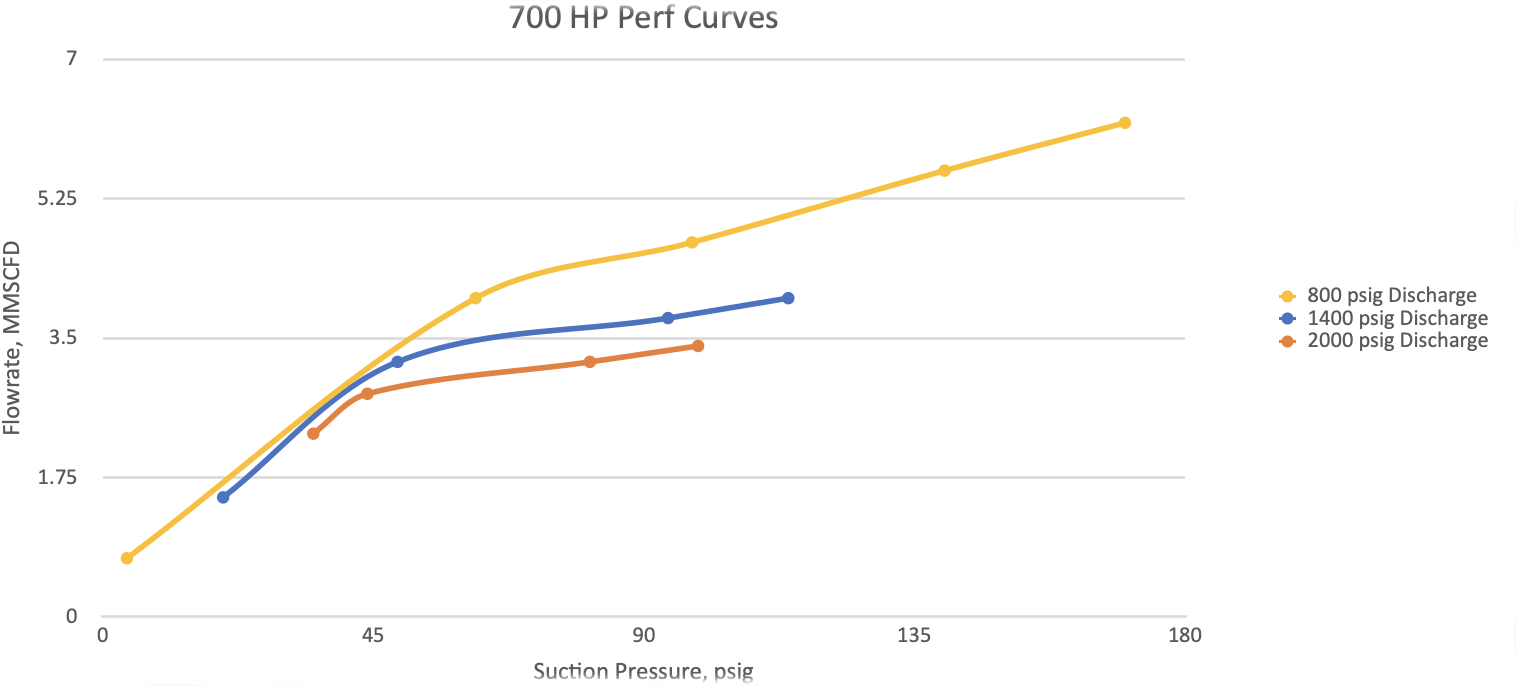

700HP-JGJ/4 Electric Compression

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA3 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel

- Rugged four-runner I-beam skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Electric Heat Tracing

- Insulated scrubbers

- Automatic makeup/recycle valve

Compressor: Ariel JGJ/4

Cylinder Size MAWP

1st Stage Cylinders (2) 9.75” RJ 635 psig

2nd Stage Cylinder 6.375” RJ 1270 psig

3rd Stage Cylinder 3.875” RJ 2200 psig

Cooler: 72” Horizontal Forced Draft

Control System: Murphy/TECO

Overall Dimensions: 34’ L X 13’ W X 11’ H

Shipping Weight: 91,100 lbs

Gas Compressors

For over two decades McClung Energy Services has designed and fabricated some of the most reliable gas driven compression packages in the industry. Whether you’re looking for a custom engineered solution or a pre-packaged unit, we’re here to make sure you get the most reliable gas compression system available to meet the unique needs of your application.

With gas compression packages ranging from 150 HP to 800+ HP, we’re uniquely positioned to deliver solutions that meet production goals from the Bakken, Marcellus, Permian, and everywhere in-between. And, our insistence on only using the highest quality components from strategic partners like Cummins, Caterpillar, Ariel, and Murphy means you can count on superior performance in the harshest environments.

Ultimately, what separates us from other manufacturers is our commitment to you, our customer. From custom engineering services and operator training to onsite field service, we’re with you every step of the way to ensure that your gas compression package delivers the performance required to meet your goals.Reach out today to see which gas compression solution will work best for your application.

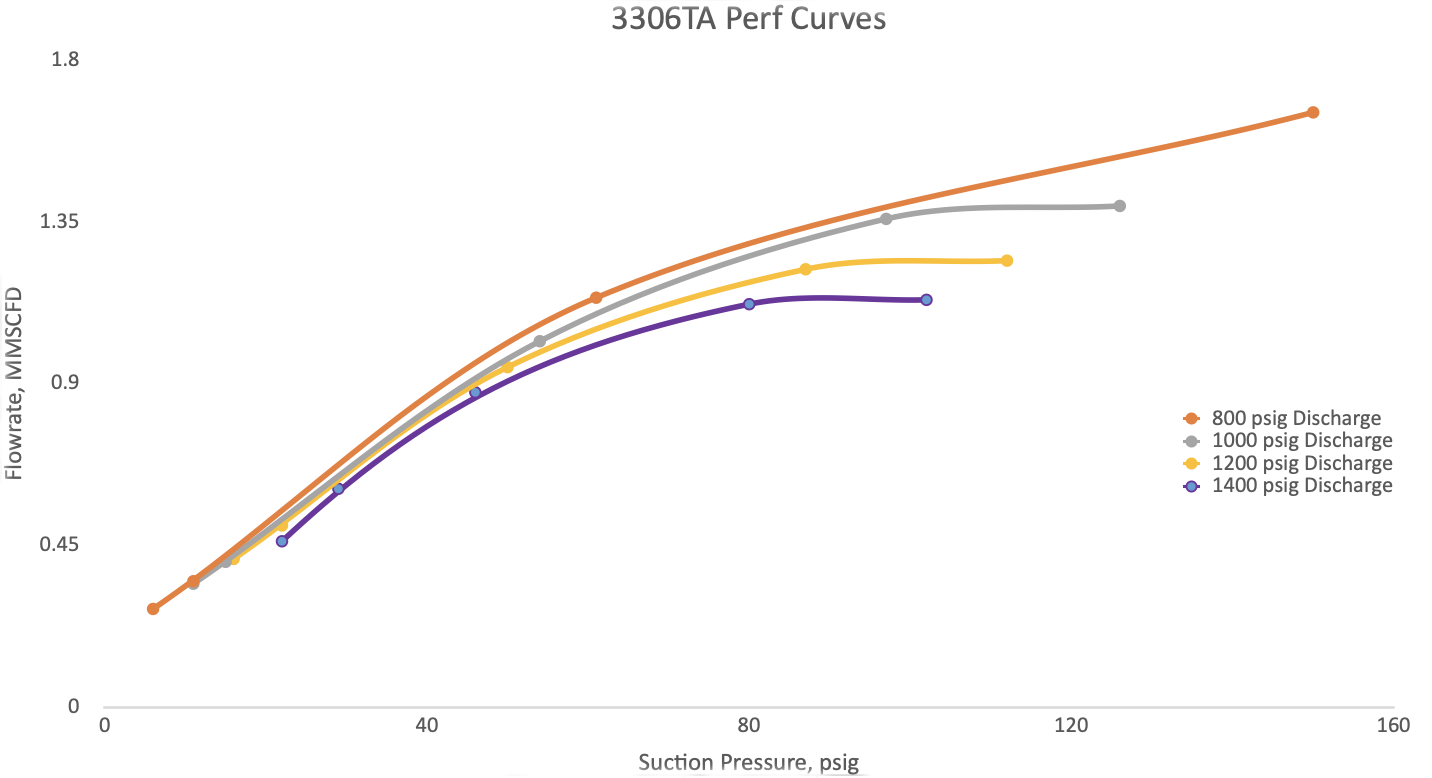

3306BTA-JGQ/2 GAS COMPRESSION

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

Compressor: Ariel JGQ/2

Cylinder Size MAWP

1st Stage Cylinder 7.5” JG 600 psig

2nd Stage Cylinder 5.125” P10-HE 1200 psig

3rd Stage Cylinder 3.25” P11-CE 1800 psig

Cooler: 72” Induced Draft, Vertical Discharge

Control System: Murphy/EICS

Overall Dimensions: 23’ L X 9.5’ W X 12’ H

Shipping Weight: 41,000 lbs

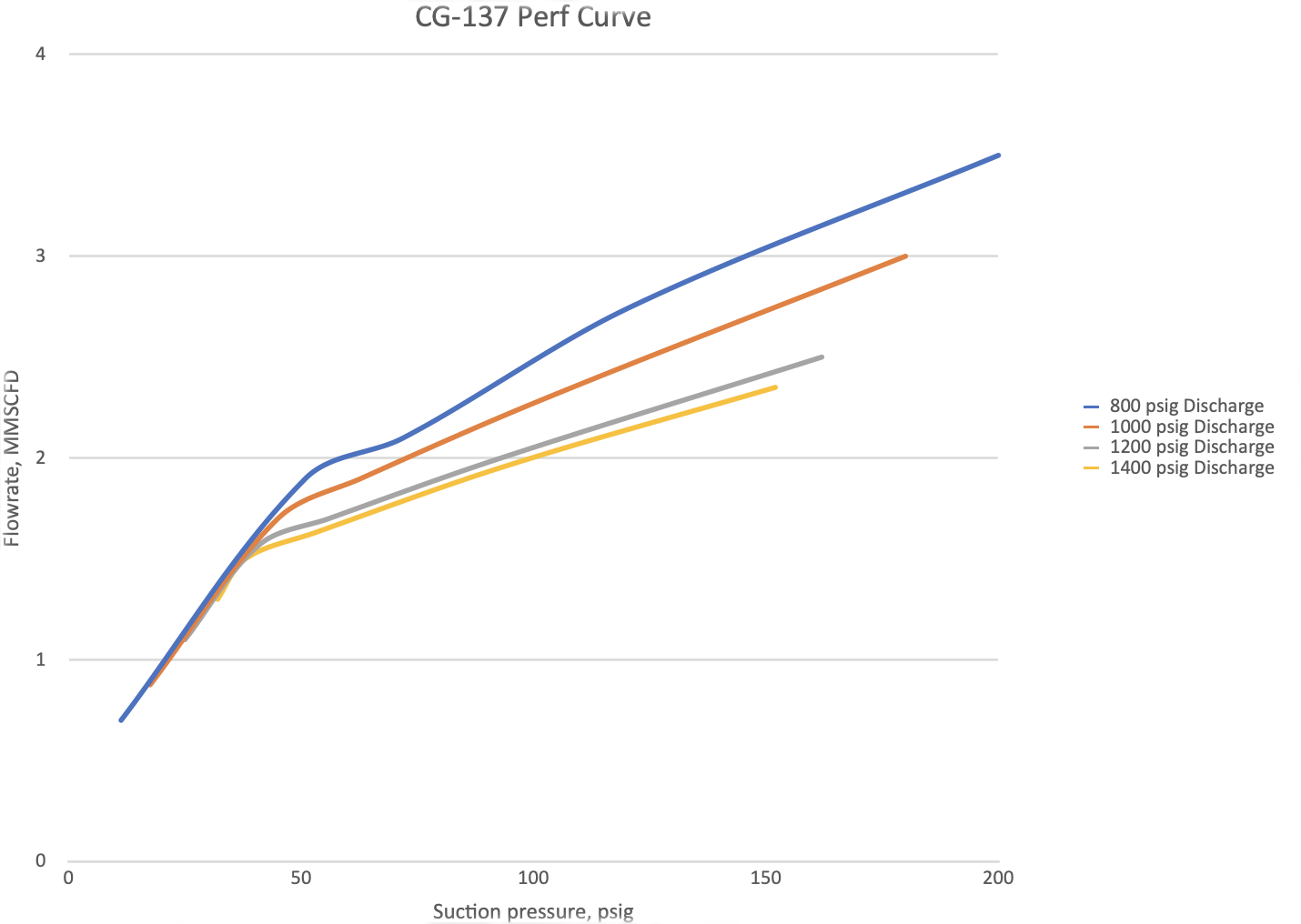

CG-137-JGA/4 GAS COMPRESSION

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with CAT ADEM Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

.png)

Compressor: Ariel JGA/4

Cylinder Size MAWP

1st Stage Cylinders (2) 7.5” JG 600 psig

2nd Stage Cylinder 5.125” JG 865 psig

3rd Stage Cylinder 3.375” JG 1640 psig

Cooler: 93” Forced Draft, Vertical Discharge

Control System: Murphy/EICS

Overall Dimensions: 27’ L X 14’ W X 12’ H

Shipping Weight: 51,000 lbs

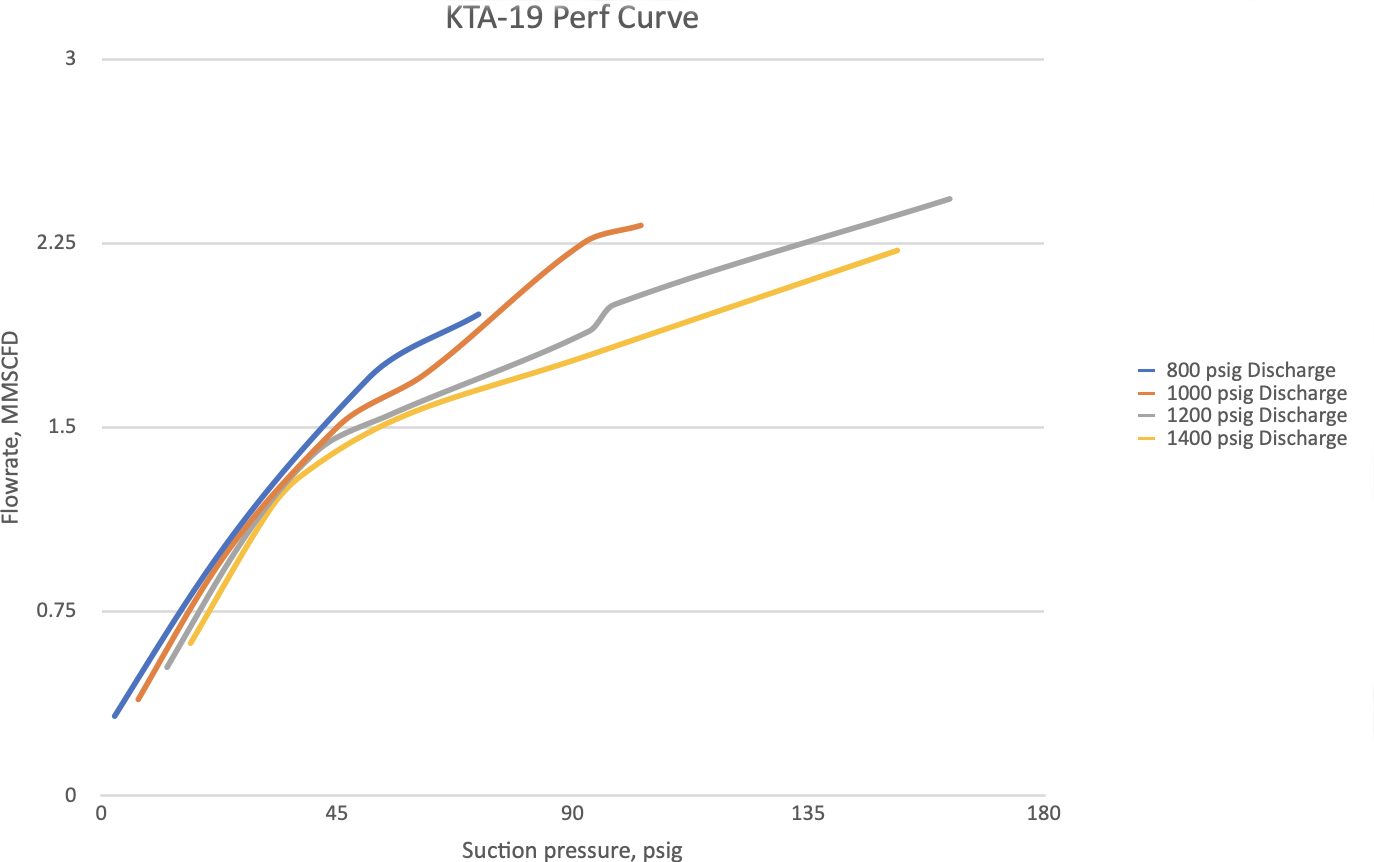

KTA-19-JGA/4 GAS COMPRESSION

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

Compressor: Ariel JGA/4

Cylinder Size MAWP

1st Stage Cylinders (2) 7.5” JG 600 psig

2nd Stage Cylinder 5.125” JG 865 psig

3rd Stage Cylinder 3.375” JG 1640 psig

Cooler: 93” Induced Draft, Vertical Discharge

Control System: Murphy/EICS

Overall Dimensions: 27’ L X 13’ W X 12’ H

Shipping Weight: 52,600 lbs

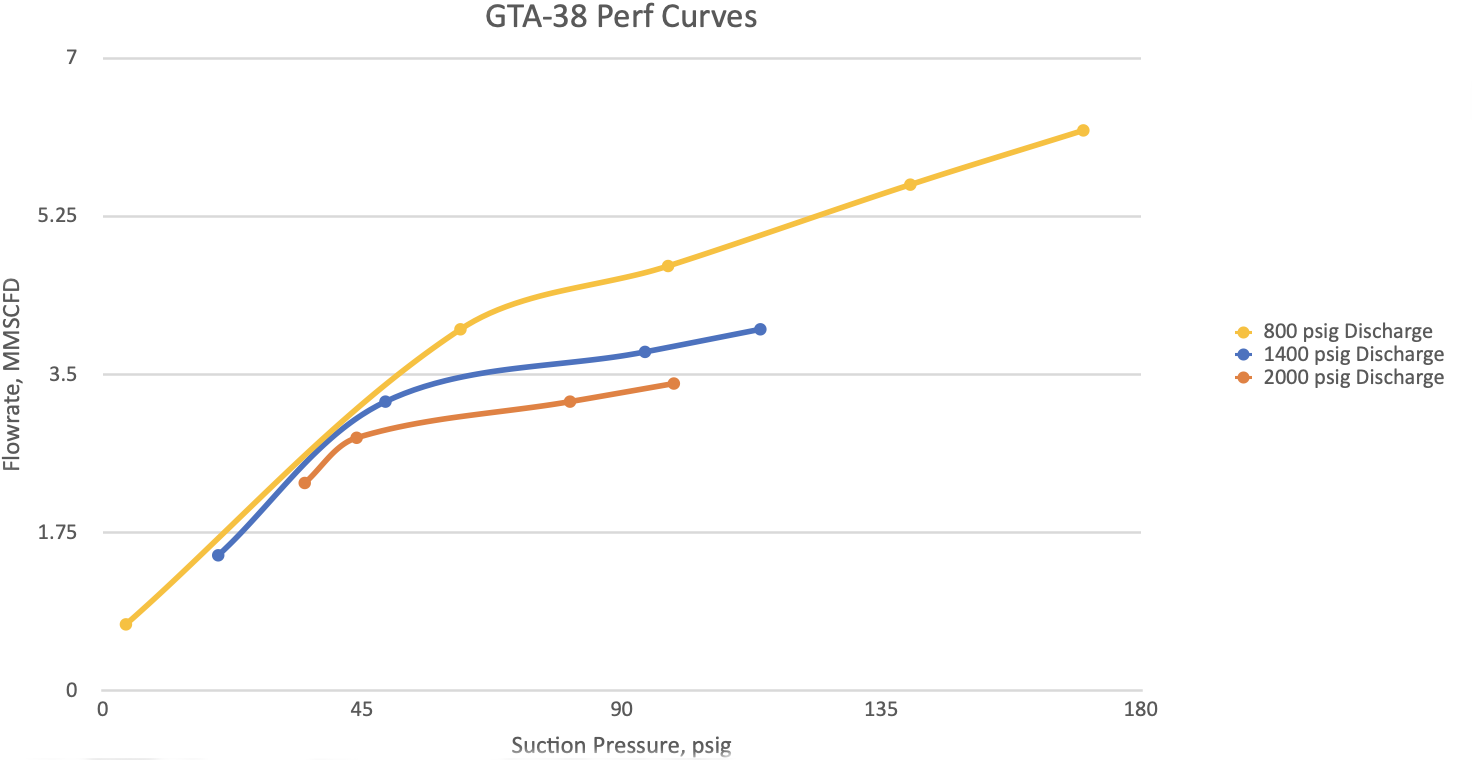

GTA-38-JGJ/4 GAS COMPRESSION

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Connections for future automatic makeup/recycle valve

Compressor: Ariel JGJ/4

Cylinder Size MAWP

1st Stage Cylinders (2) 9.75” RJ 635 psig

2nd Stage Cylinder 6.375” RJ 1270 psig

3rd Stage Cylinder 3.875” RJ 2200 psig

Cooler: 81” Forced Draft (2 fan)

Control System: Murphy/EICS

Overall Dimensions: 40’ L X 14’ W X 19.5’ H

Shipping Weight: 90,100 lbs