HPGL

High-Pressure Gas Lift (HPGL) is an artificial lift methodology that replaces failure-prone downhole ESPs with special surface compression equipment. High-pressure line gas is injected down the tubing and deep into the well, producing up the annulus. This means that 100 percent of the lift system is on the surface.

- Delivering the same or better production volumes but with much lower maintenance costs, since there are no downhole ESPs to fail (ESP failures can cost hundreds of thousands of dollars annually, depending on the region)

- Improving uptime and overall cost of ownership, since both Non-Productive Time (NPT) and maintenance costs are both reduced

- Running on line gas, so the gas lift system is not tethered to the need for a nearby power grid—perfect for remote wells.

- Navigating deviated holes, doglegs, sandy formations and other situations more effectively for better management of bottom-hole pressure as a whole.

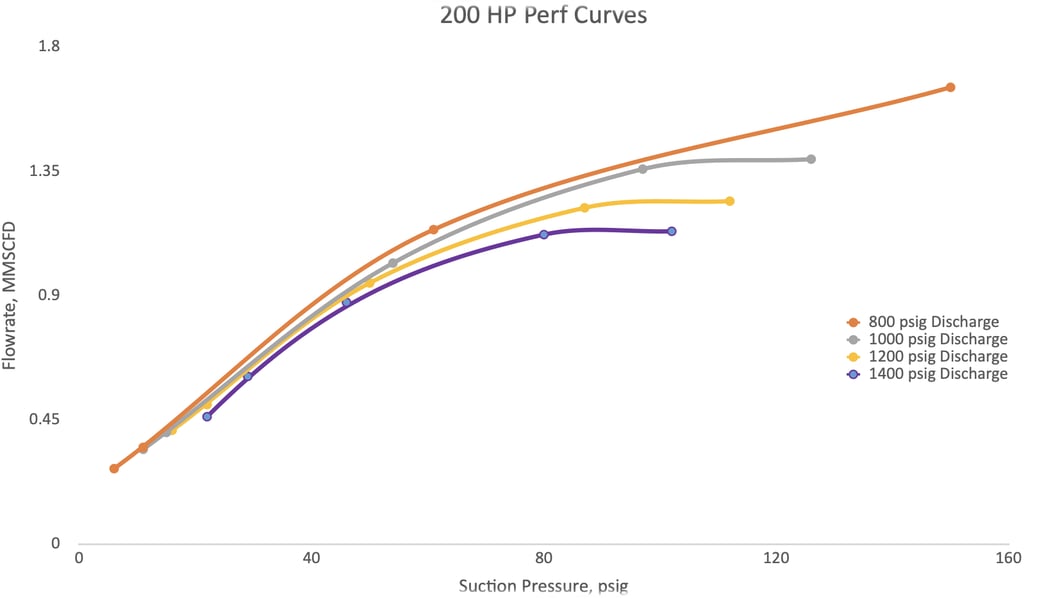

200HP-JGQ/2

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel

- Rugged four-runner I-beam skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Electric Heat Tracing

- Insulated scrubbers

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

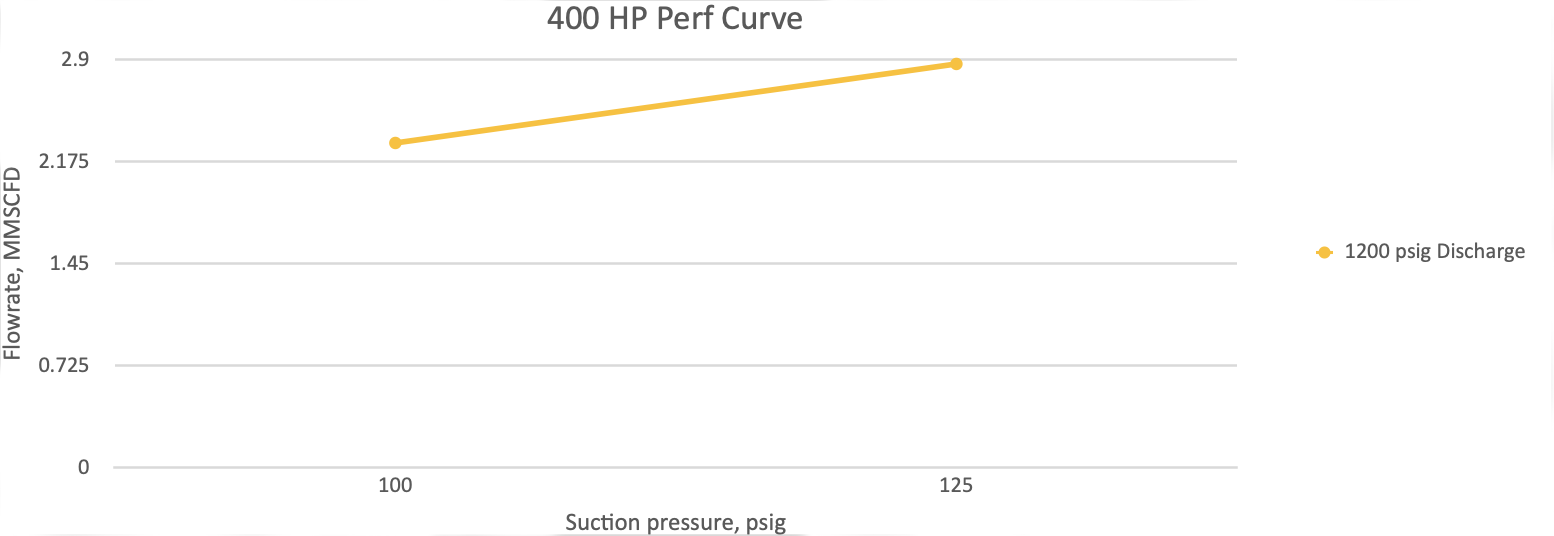

400HP-JGA/4

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA3 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel

- Rugged four-runner I-beam skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Electric Heat Tracing

- Insulated scrubbers

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

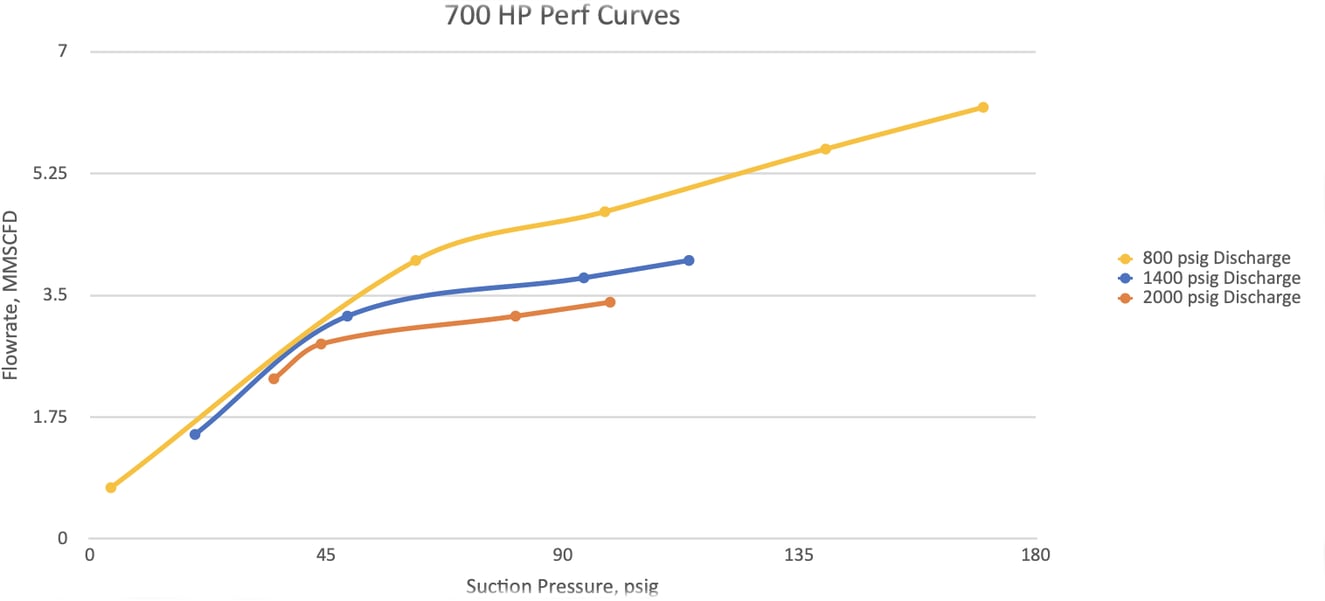

700HP-JGJ/4

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA3 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel

- Rugged four-runner I-beam skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Electric Heat Tracing

- Insulated scrubbers

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

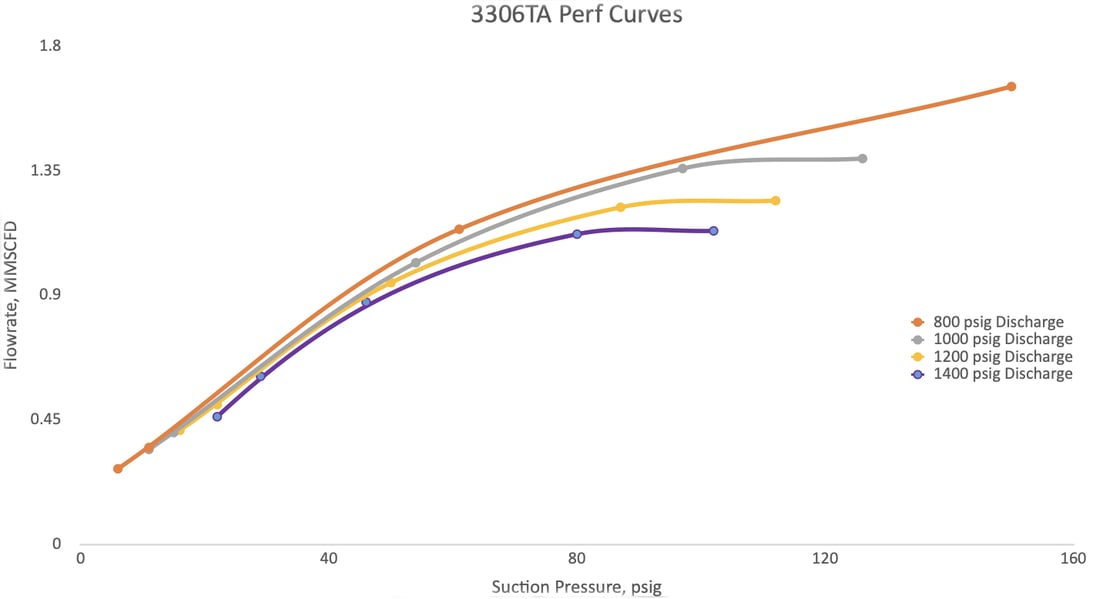

3306TA-JGQ/2

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

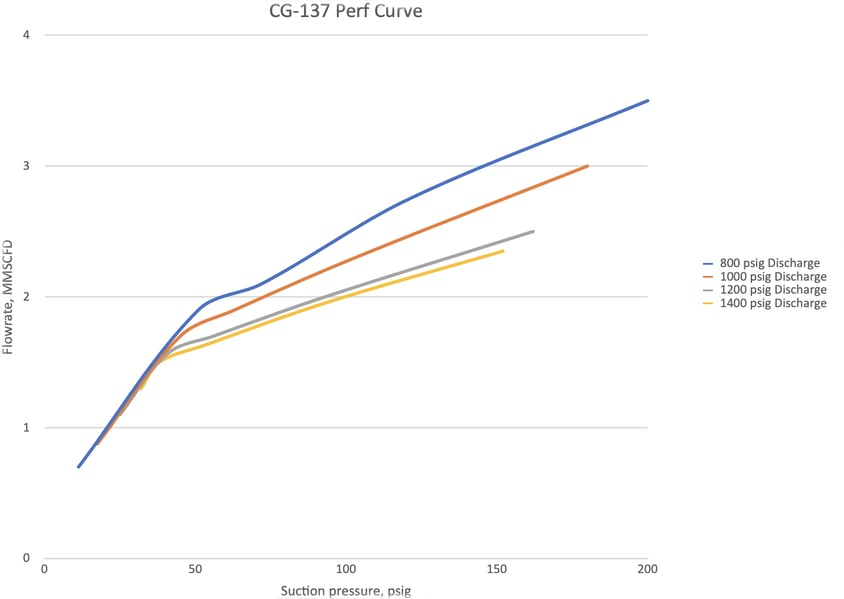

CG-137-JGA/4

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with CAT ADEM Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

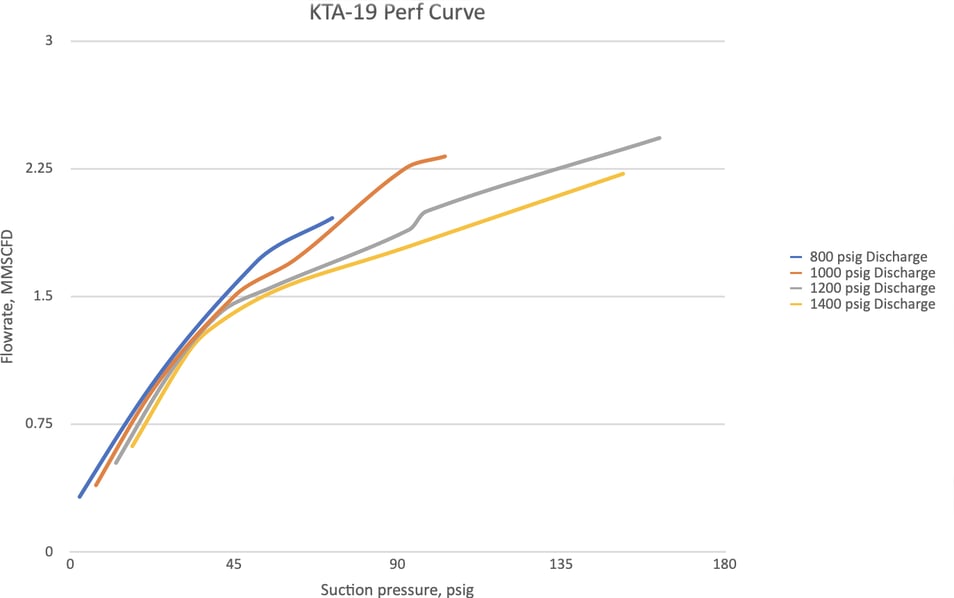

KTA-19-JGA/4

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

.jpg)

Legacy Units Description and Performance Curves

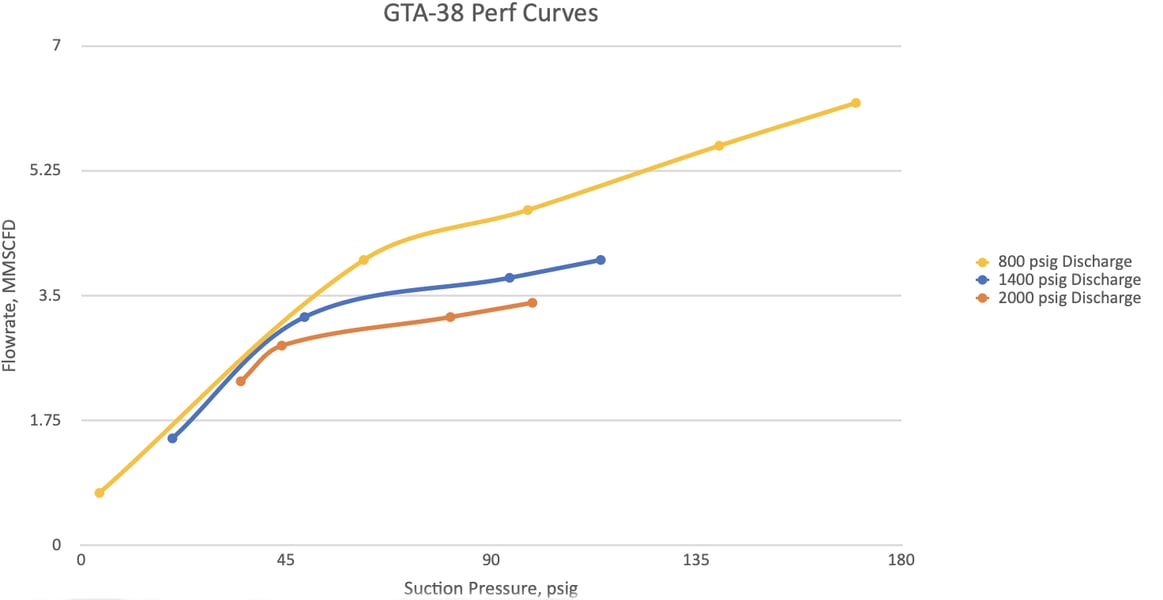

GTA-38-JGJ/4

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Connections for future automatic makeup/recycle valve

.jpg)

Legacy Units Description and Performance Curves

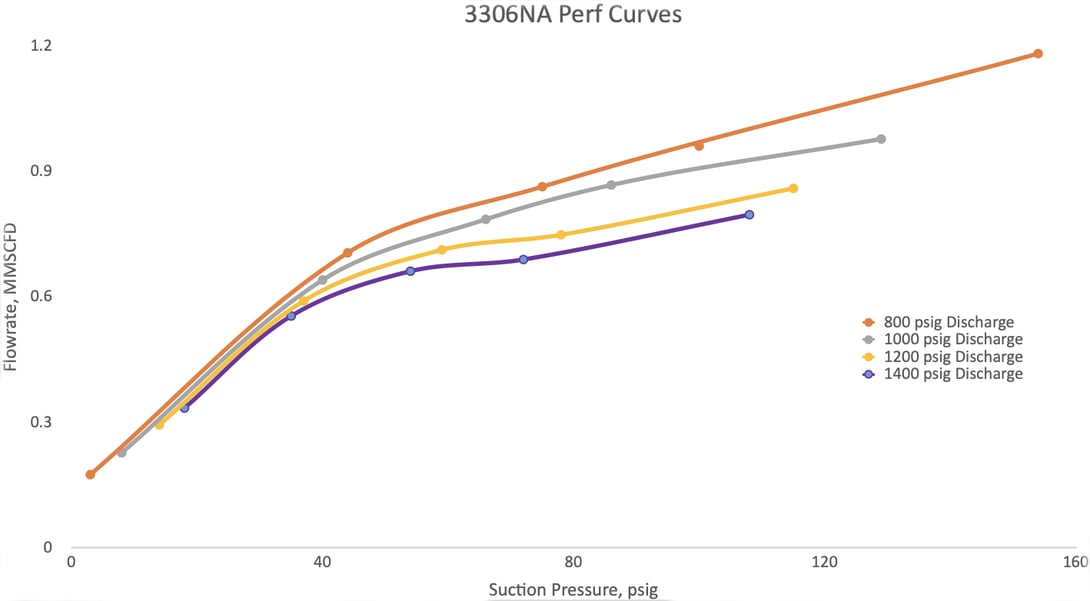

3306NA-JGQ/2

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- API 5th Edition DA2 pulsation and vibration analysis performed for smooth operation

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

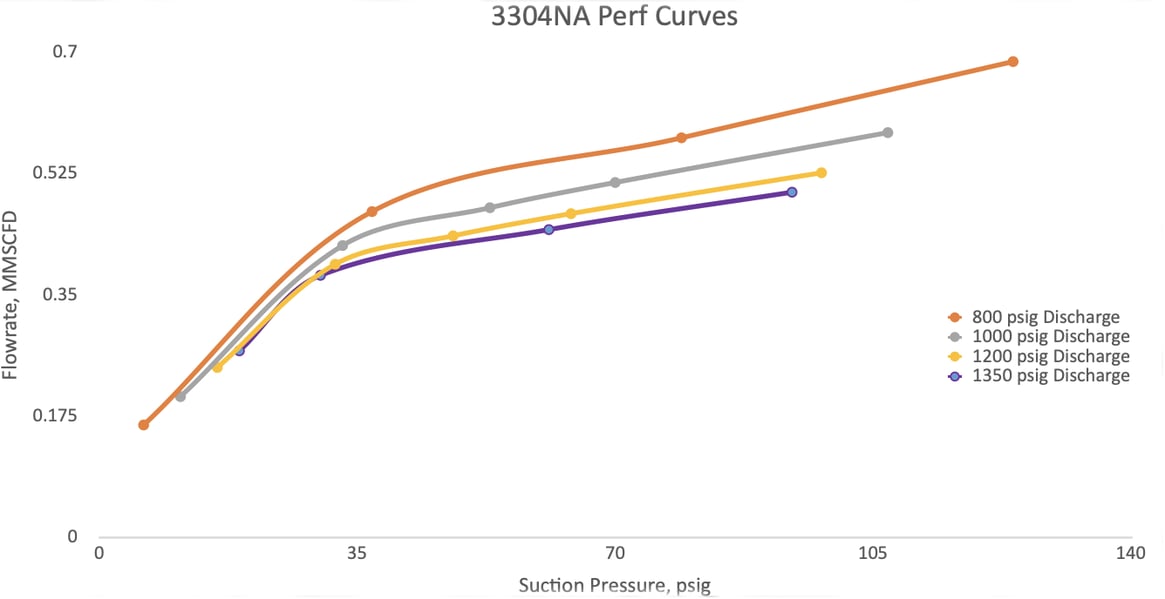

3304NA-JGP/2

Package Features:

- Scrubbers designed to ASME Section VIII Division 1.

- Piping designed and tested to ASME B31.3

- Murphy Centurion Panel with EICS Emissions Control

- Rugged structural steel skid with environmental containment

- Hot gas bypass on after-cooler section

- Inlet spool piece with basket strainer

- Suction or Discharge based speed control

- Automatic cooler louvers

- Engine Gylcol Heat Tracing

- Insulated scrubbers

- Coalescing type fuel gas filter for maximum engine protection

- Automatic makeup/recycle valve

Legacy Units Description and Performance Curves

Electric Compressors

We’re leading the way in helping companies who want superior electric drive compression solutions. Access to electrical infrastructure is spreading to more basins, making the switch to electric compressors easier.

We can modify any of our standard electrical well-pad compression packages to meet your particular specifications. And we provide user training to get your teams comfortable using well-pad compression from a new power supply.

Gas Compressors

Small and midsize gas-driven well-pad compression in the 200-800 HP range remains a staple for agile companies.

They’re ideal for those who want to optimize oil recovery and gas gathering. And they’re where we began focusing on standard packages for the industry—and where we’re still leaders with our quality equipment. Our gas well-pad compression packages are operating in all major basins in the US, including the Permian and Bakken basins.

Custom Equipment

Title for this information:

- Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

- Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

Title for this information:

- Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

- Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

- Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

- Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

Title for this information:

- Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

- Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

- Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

- Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.